Meta Description: Having the right operating theatre lighting system is key for patient safety and surgical teams comfort. This article highlights the details of OT lights and how to maintain them for an efficient surgical procedure.

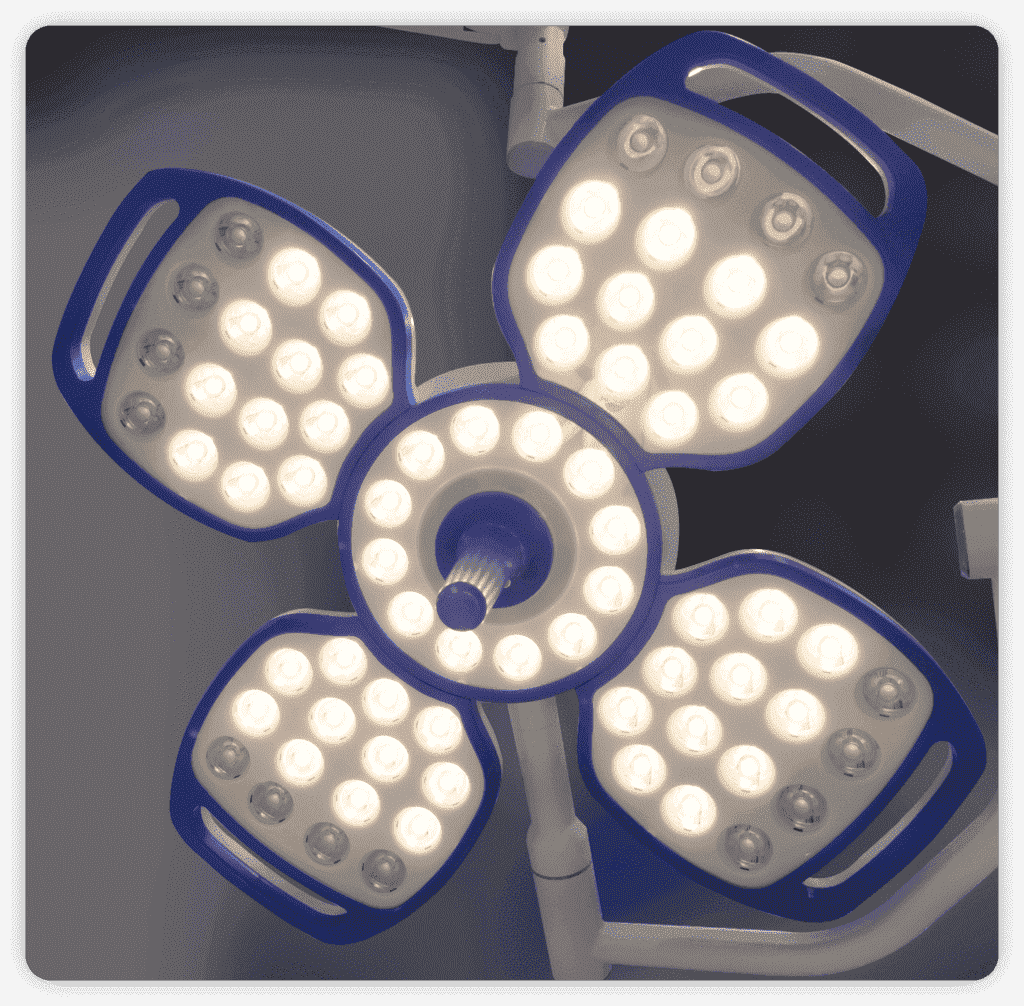

Operating Theatre Lights, also known as surgical lights or surgical lighting, are lighting equipment mainly used in hospital operating rooms. However, they can also be used in various locations throughout the hospital to provide exceptional lighting for different procedures.

These medical equipment are used by clinicians, surgeons, and proceduralists to illuminate the operative site on a patient for optimal visualization during a procedure and provide high quality lighting.

Unlike several other types of electrical light source, an efficient surgical light like Light Emitting Diode (LED) lights is capable of providing bright light without the trade-off of excessive heating on both patients and staff.

Around 1830 – 1860, operating theatres were constructed in the southeast-facing rooms with the hope of getting in as much natural sunlight as possible.

But this came with limitations like the inability to perform surgery at dusk, the uncertainty of having the perfect weather during the day, and casting shadows when light is blocked by a doctor.

Although they were able to make the light field brighter by installing mirrors at the four corners of the operating room ceiling which were used to reflect sunlight.

A simple and practical solution at the time, even though it didn’t solve the problem.

A step in innovation in surgical lights came in the 1920s when Weilan, a French Professor made the earliest surgical lights in the United Kingdom.

He placed many narrow planes on the dome and placed a 100-watt lamp in the center of the refractive lens which showed a tapered shape.

This innovation got rid of the need for a surgical team to keep tabs on the weather and other factors in the preparation of surgery.

In the 1930s and 1930s, there was another reform in operating room lights as France’s single light Surgical Lights and the US orbital Surgical Lights came into play.

However, it still had its limitations.

Although the incandescent bulbs reached over 200W, they had a large surface filament which meant the optical path was uncontrolled, making it difficult to focus.

Also, the reflector was polished with copper which made it difficult to reflect, resulting in extremely poor lighting.

In a bid to improve operation theatre lights and attain maximum illumination in the 1950s, people began to increase the number of light sources.

These multi-lamp lighting systems were mostly used in Europe and Japan.

They had between 4 to 14 small reflective holes with a 15W or 25W mirror light bulb placed in its center, which is made into a reflective hood with aluminum.

This was able to improve light intensity up to 40,000 lux of central illuminance.

Although the surgical lighting was improved in the aspect of illumination, there was an increase in temperature as more bulbs were added to the surgical lights.

This caused medical team discomfort and also caused drying of the surgical site which affected recovery after the operation.

However, with the emergence of integral reflector lamps in the 1980s which came as a result of the continuous advancement of computer technology,

surgical light sources now used halogen bulbs and reflective surface which was designed with CAD (computer-aided design) technology.

With a surface formed by industrial stamping to form a polygon mirror and multiple reflecting surfaces overlapping with the surgical light to form a homologous light beam that is as bright as daylight without shadows.

It was also very uniform when the surgeon’s shoulders or head are occluded. The only limitation of this surgical light at the time was its relatively short life span and need for frequent lamp replacement.

With the 21st century came the LED surgical lights innovation, which was required given how surgical procedures have become more complex than it was. In addition to improving basic performance parameters such as light field diameter, illuminance and temperature control, there are also strict requirements for the uniformity of contrast of surgical lights.

Compared to halogen lamps, LED lighting as a cold light source can significantly control the utilization rate of temperature rise and light energy conversion. With almost zero heat radiation and a life span 60 times longer than that of halogen lights.

There’s no doubt that with the continuous emergence of new technologies and new materials, surgical lights will have further development in the near future and improve illumination of the surgical site.

Different types of surgical lights play different roles in illumination before, during, and after a medical procedure. There are two classifications of surgical lights. They are the conventional (or incandescent) and the Light-emitting diodes (LED).

Halogen lights were historically considered conventional surgical lights and utilize a type of incandescent bulb filled with halogen gas to produce light inside of the lamp.

Halogen enables the filament to run at a higher temperature. This is because even though the tungsten is evaporated off the filament faster at the higher temperature, the halogen chemically reacts with the evaporated tungsten.

This forms a tungsten halogen compound which diffuses back to the filament where the higher temperature causes it to separate into tungsten and halogen, depositing the tungsten back on the filament.

Their lower filament correlated color temperature at 3,000K gives them their typical orange-yellow, warm appearing cast rather than white.

Standard halogen lights have a short life span which averages approximately 6 months or shorter. This is especially true if the bulbs are touched by bare hands because the oil from a person’s finger can heat the bulbs thereby shortening its already short life span.

Also, its outrageously high number of hazardous features from something as simple as a skin burn when in direct contact to infrared radiation that could cause several other ailments like eye fatigue warranted the need for Tungsten Halogen lights. This is an incandescent light with a filament inside of the bulb that is filled with halogen gas.

The filament of a Tungsten Halogen Lamp has two purposes which are to generate light and heat necessary to obtain a wall temperature exceeding 25˚C.

The combination of Tungsten and halogen gas produces a chemical reaction redepositing evaporated tungsten on the filament. The process allows the filament to operate at a higher temperature and produce light with higher efficacy and color temperature.

LED eventually surpassed conventional halogen lighting sources as the preferred light source and became a standard offering in many operating rooms and procedural areas. LED lights are solid-state semiconductors devices that emit light as currents flow through them.

With a more refined energy usage and significantly fewer energy requirements than halogen, the LED surgical light system produces higher quality illumination in operating rooms.

The plastic encapsulant and the lead frame compose most of the bulb’s structure and the light-generating chip is comparatively small in comparison. Light is generated inside the chip, a solid crystal material when current flows across the junctions of different materials. The spectral emission of the LED light depends on the materials used to form the semiconductor.

The composition of the materials determines the wavelength and color of the light. Initially LED surgical lighting used a combination of red, green, blue, and white LEDs to achieve a bright white illuminance. This strategy was the primary means to achieve high light output superior to what using all white LEDs could produce.

The halogen surgical lights are made of halogen and quartz glass. They are incandescent and offer a very bright and intense light. For years, they were the best operating room lighting on the market. It is the closest thing to the traditional incandescent lamp that people used at home.

However, they have mostly been abandoned for the LED surgical light because they raise the temperature in the area where they are used. Also, halogen bulbs can also suffer untimely blackouts, which is a risk for patients and a problem for surgeons who can sweat or, even worse, lose the lighting of the area.

The LED surgical lamps revolve around the diode, which distributes the flow of electrical current in one direction so that electricity is used much more efficiently to achieve powerful lighting in the operating room.

However, unlike halogen lamp, a LED surgical light does not generate as much heat and can be touched by hand without the risk of burns. All these advantages offered by a LED surgical light facilitate safety and comfort in the operating room.

Essential practices and procedures are required to be put in place to ensure the safe operating of medical equipment. Here are some of the ways to maintain surgical lighting:

The operating theatre is a demanding workplace that requires high levels of vigilance for long periods, often in compromised physical positions while applying force. The demands upon the user are great. Technology, such as surgical lighting, is used to assist the surgical team in ensuring the conditions are as beneficial as possible.

However, the pros are somewhat matched by the cons which need to be carefully balanced to ensure that the best performance is delivered. It is imperative that once surgical lighting systems are installed, their performance will be judged by the users not on a set of measurable criteria, but on their “adequacy”, which will be a function of the user’s preferences.

Whilst surgical lighting performance can be described by the technical criteria associated with the surgical light manufacturers, the effectiveness of this medical equipment will be measured by the users.

Accordingly, the purchase of lighting based on specification alone is an unreliable and possibly highly flawed approach.

The inclusion of informed users early in the procurement process will help ensure that the final purchases made are fit for purpose and offer the best value when all criteria are aggregated. These criteria need to be greater than just price and technical values.

Therefore, it is important to know the different types of operating room lamps (halogen or LED surgical lighting), their advantages and disadvantages, and, of course, to ensure electrical safety in the operating room.